Applications and markets

Heat treatment of materials, especially metals, serves to improve the material properties. For example, materials can become harder, tougher and more corrosion-resistant through the thermo-chemical reactions involved, which, in turn, increases the product quality and enhances the service life.

Fluidized bed heat treatment is preferably used for hardening, annealing, tempering or nitriding and nitrocarburizing materials. However, quenching and aging are also possible and offer major benefits for some industries. The emphases of the applications are energy-saving hardening of tools, low-warping or non-warping part treatment as well as the quick treatment of special parts.

Automotive industry

The benefits of SCHWING systems for the automotive industry comprise the great option of shaping and hardening, for example, body parts with the help of extremely uniform heat treatment. The fluidized bed has many advantages for ferrous and nonferrous metal castings, for example engine blocks or other components made of aluminium by high pressure die casting. Apart from the especially gentle and thus error-free heat treatment, this technology also helps with the high production pressure of automotive manufacturers and their suppliers: It saves more time and thus also energy compared to most of the comparable applications. Additionally sand core removal and heat treatment can be performed in the same fluidized bed.

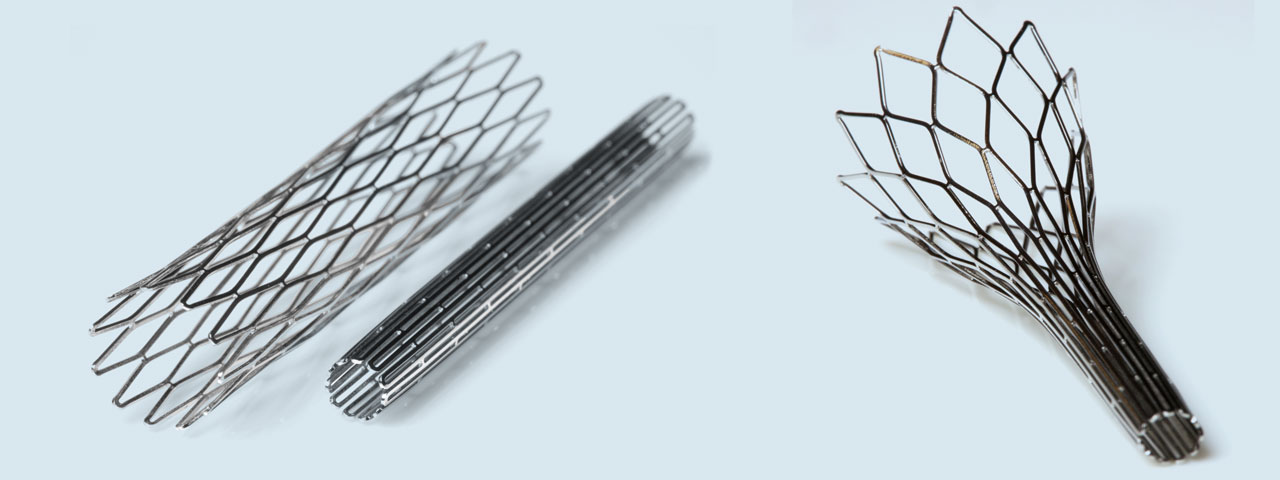

Medical technology

Medical technology represents a high-precision industry governed by the highest quality standards. This applies also to the production sector of heat treatment. For example, stents, with their basic structure from stainless steel, require precise shaping. These life-saving medical products are often so small that their uniform treatment and shaping presents problems. With the heat treatment processes from SCHWING stable shaping and hardening, which is gentle on the material, is achieved easily and reliably.

Versatile applications

Many other high-quality and sometimes also sensitive materials can only be used for medical purposes through heat treatment. However, heat treatment is a very sensitive process since uneven temperature management can quickly cause material damage. Heat treatment must therefore be applied with great care, and the special requirements of different materials and material components must be taken into account. To prevent these constantly rising requirements from driving up the manufacturing costs even further, SCHWING builds and operates especially efficient heat treatment systems, which can also be used economically for small batches.

Fluidized bed process technology

Apart from the specific heat treatment of metal parts in a fluidized bed, SCHWING offers comprehensive expertise in the construction of specific fluidized bed reactors for the thermo-chemical conversion of powdery substances through the cross-flow of reaction gases in variable atmospheres.

More information about “Fluidized Bed Process Technique” is available here or at www.fluidized-bed-process-technique.com.